Catalog

Tags

Understanding Shrinkage in Injection Molding: Causes, Effects & Solutions

Injection molding is one of the most widely used manufacturing processes for producing plastic parts, but it comes with its share of challenges. Among these, shrinkage stands out as a critical factor that can significantly impact product quality and dimensional accuracy.

Shrinkage in injection molding refers to the reduction in size of a plastic part as it cools and solidifies after being injected into the mold cavity. This phenomenon occurs because most plastic materials have higher densities in their solid state than in their molten state, causing the material to contract as it transitions between these phases.

Understanding shrinkage is essential for manufacturers because it affects everything from product functionality to assembly processes. When not properly accounted for, shrinkage can lead to defective parts that don’t meet specifications, resulting in increased costs and production delays.

In this comprehensive guide, we’ll explore the science behind shrinkage, examine its various causes, discuss measurement techniques, and provide practical solutions to control this inevitable aspect of plastic injection molding.

Table of Contents

- What is Shrinkage in Injection Molding?

- The Science Behind Plastic Shrinkage

- Different Types of Shrinkage

- Key Factors Affecting Shrinkage Rates

- Measuring and Calculating Shrinkage

- Effects of Shrinkage on Product Quality

- Methods for Controlling Shrinkage

- Material Selection and Shrinkage Considerations

- Real-World Case Studies

- Future Trends in Shrinkage Control

What is Shrinkage in Injection Molding?

Shrinkage in injection molding is the dimensional reduction that occurs when a molten plastic part cools and solidifies in the mold. This contraction happens because the plastic material becomes more dense as it transitions from a liquid to a solid state.

The amount of shrinkage varies depending on the material used, but typically ranges between 0.2% and 3.0% of the part’s dimensions. For example, a 100mm long part made from a plastic with 1% shrinkage would measure 99mm after cooling.

Shrinkage isn’t uniform across all directions or sections of a part. Variations in wall thickness, mold temperature, and material flow can create differential shrinkage, leading to warpage or dimensional inaccuracies. This makes shrinkage compensation one of the most challenging aspects of mold design.

Manufacturers must account for anticipated shrinkage during the mold design phase by making the mold cavity slightly larger than the desired final part dimensions. This compensation is called the “shrinkage allowance” and is based on material-specific shrinkage data provided by resin manufacturers.

For more information on mold design considerations, check out our guide on injection mold design basics.

The Science Behind Plastic Shrinkage

To truly understand shrinkage, we need to examine the molecular behavior of polymers during the injection molding process. When plastic is heated to its melting point, the polymer chains gain energy and move apart, creating greater free volume between molecules.

As the molten plastic is injected into the mold and begins to cool, several physical changes occur simultaneously. The polymer chains lose thermal energy and begin to pack more closely together, reducing the free volume between molecules and increasing the material’s density.

Crystalline polymers exhibit more significant shrinkage than amorphous polymers because they undergo a more organized packing of molecules during crystallization. The degree of crystallinity directly affects the shrinkage rate, with highly crystalline materials like polypropylene (PP) showing shrinkage rates of 1.5-3.0%, while amorphous materials like polystyrene (PS) typically shrink only 0.2-0.8%.

The cooling rate also significantly impacts shrinkage. Rapid cooling allows less time for polymer chains to organize, resulting in lower shrinkage but potentially creating internal stresses. Slower cooling permits more complete crystallization but increases shrinkage.

According to research from ScienceDirect, the specific volume of most plastics decreases by 5-25% as they transition from melt to solid state, explaining why shrinkage is an inherent characteristic of the injection molding process.

Different Types of Shrinkage

Shrinkage in injection molding isn’t a single uniform phenomenon but rather manifests in several distinct forms that engineers must consider during product design and process optimization.

1. Mold Shrinkage

Mold shrinkage refers to the dimensional change that occurs while the part is still in the mold. This initial shrinkage happens as the plastic cools from its injection temperature down to the mold temperature. Mold shrinkage accounts for about 75-90% of the total shrinkage in most cases.

2. Post-Mold Shrinkage

After ejection, the part continues to shrink as it cools to ambient temperature. This post-mold shrinkage typically accounts for the remaining 10-25% of total shrinkage. Some materials, particularly semi-crystalline ones, may continue to shrink for hours or even days after molding due to slow crystallization processes.

3. Directional Shrinkage

Plastics often shrink differently in the flow direction compared to perpendicular directions. This anisotropic behavior results from molecular orientation during filling. Flow-direction shrinkage is typically 1.5-3 times greater than transverse shrinkage for many materials.

4. Differential Shrinkage

Variations in wall thickness within a part create differential shrinkage rates. Thicker sections shrink more because they cool slower and have more time for polymer organization. This can lead to warpage, sink marks, or internal stresses if not properly addressed in design.

Understanding these different shrinkage types is crucial for implementing effective compensation strategies. For complex parts, engineers often use mold flow analysis software to predict and account for these variations.

Frequently Asked Questions

A: The shrinkage rate is typically provided by material suppliers in their technical datasheets. It’s expressed as a percentage or mm/mm value. To calculate actual shrinkage: Shrinkage = (Mold Dimension – Part Dimension) / Mold Dimension × 100%. For accurate results, measure parts after they’ve fully stabilized (usually 24-48 hours after molding).

A: Volumetric shrinkage refers to the total volume reduction of the plastic as it cools, while linear shrinkage refers to dimensional changes along specific axes. Most datasheets provide linear shrinkage values because these are more practical for mold design. Volumetric shrinkage is typically about three times the linear shrinkage value.

A: No, shrinkage is an inherent property of plastic materials and cannot be completely eliminated. However, it can be controlled and compensated for through proper mold design, material selection, and process optimization. The goal is to achieve predictable, consistent shrinkage that can be accounted for in the design phase.

Conclusion

Shrinkage in injection molding is a complex but manageable aspect of plastic part manufacturing. By understanding its causes, accurately predicting its effects, and implementing appropriate control measures, manufacturers can produce high-quality parts with consistent dimensions.

Key takeaways include:

- Shrinkage is inevitable but predictable for most materials

- Material selection significantly impacts shrinkage behavior

- Proper mold design can compensate for anticipated shrinkage

- Process parameters offer powerful control over shrinkage rates

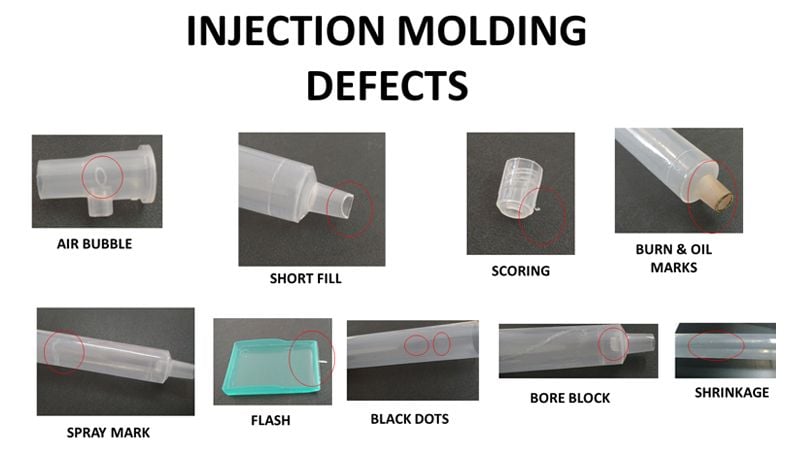

For those looking to deepen their understanding of injection molding processes, we recommend reading our article on common injection molding defects and how to avoid them.

Need Precision CNC Machining for Your Mold Components?

We specialize in custom CNC machining of mold inserts, slide cores, ejector plates, mold bases, and lifters

all made to your exact drawings and specifications.

👉 Let’s Build Your Next Project Together!

Tell us your needs and upload your drawings — we’ll get back within 24 hours.