Catalog

Tags

Full Service Mold Making: The Complete Process from Design to Production

In today’s manufacturing landscape, full service mold making has become an essential process for producing high-quality plastic and metal components across industries. But what exactly does “full service” entail, and how does the mold making process work from start to finish?

This comprehensive guide will walk you through every aspect of full service mold making, from initial design concepts to final production. Whether you’re a product designer, engineer, or manufacturing professional, understanding this complete process can help you make better decisions for your projects.

We’ll explore the different types of molds, the step-by-step manufacturing process, key technologies involved, and the benefits of choosing a full service provider over partial service options. By the end, you’ll have a clear picture of how modern mold making can bring your product ideas to life.

Table of Contents

- What is Full Service Mold Making?

- Types of Molds in Manufacturing

- The Design Phase: From Concept to CAD

- Material Selection for Mold Making

- Mold Fabrication Process

- Precision Machining Techniques

- Finishing and Polishing Processes

- Testing and Validation

- Production Integration

- Benefits of Full Service Mold Making

- Frequently Asked Questions

- Conclusion

What is Full Service Mold Making?

Full service mold making refers to a comprehensive approach to mold manufacturing that handles every aspect of the process under one roof. Unlike partial service providers that might specialize in just design or machining, full service companies manage the complete workflow from initial concept to final production.

This end-to-end service typically includes design engineering, material selection, precision machining, finishing, testing, and often production runs. The advantage is seamless coordination between all stages, reducing communication gaps and potential errors that can occur when working with multiple vendors.

Modern full service mold makers utilize advanced technologies like CAD/CAM software, CNC machining, EDM (electrical discharge machining), and 3D printing to create high-precision molds. They serve industries ranging from automotive and aerospace to medical devices and consumer products.

The full service approach is particularly valuable for complex projects where tight tolerances and specific material properties are required. It allows for continuous optimization throughout the process, as engineers can quickly make adjustments based on testing results.

According to Plastics Today, the global mold making market is expected to grow significantly, driven by demand for precision components in various industries. Full service providers are well-positioned to meet this demand with their comprehensive capabilities.

Types of Molds in Manufacturing

The world of mold making encompasses several specialized types, each suited for particular applications and production requirements. Understanding these variations helps in selecting the right approach for your project.

Injection Molds: The most common type, used for mass production of plastic parts. These molds feature complex cooling channels and ejection systems. They can be further categorized into:

- Two-plate molds (simplest design)

- Three-plate molds (for complex parts)

- Hot runner molds (for high-volume production)

Blow Molds: Used for creating hollow plastic products like bottles and containers. The process involves inflating heated plastic into a mold cavity.

Compression Molds: Primarily for thermoset materials and rubber products. Material is compressed into shape under heat and pressure.

Rotational Molds: For large, hollow products like tanks or playground equipment. The mold rotates while plastic coats the interior surfaces.

Die Casting Molds: For metal parts production using high-pressure injection of molten metal into steel molds.

Each mold type requires different design considerations and manufacturing techniques. A full service provider can advise on the optimal approach based on your material, production volume, and part complexity.

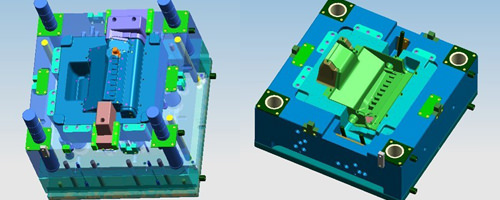

The Design Phase: From Concept to CAD

The mold making process begins with careful design, which lays the foundation for everything that follows. This phase typically consumes 30-50% of the total project time but is crucial for avoiding costly mistakes later.

Modern mold design starts with CAD (Computer-Aided Design) software, where engineers create 3D models of both the final product and the mold itself. Key considerations include:

- Parting lines (where mold halves meet)

- Draft angles (for easy part ejection)

- Wall thickness consistency

- Gate locations (where material enters)

- Cooling channel placement

- Ejection system design

Many full service providers use specialized mold design software that includes features for flow analysis, cooling simulation, and stress testing. This digital prototyping helps identify potential issues before metal is cut.

The design phase often involves close collaboration between the mold maker and the client. Experienced engineers can suggest design modifications that improve manufacturability without compromising the part’s function.

For complex projects, the design process may include creating 3D printed prototypes to validate the concept before committing to expensive mold fabrication. This iterative approach reduces risk and ensures the final mold will produce parts as intended.

Material Selection for Mold Making

Choosing the right material for a mold is critical to its performance, longevity, and the quality of parts it produces. The selection depends on factors like production volume, material being molded, required precision, and budget.

Tool Steels: The most common choice for high-volume production molds. Varieties include:

- P20 – Good balance of machinability and durability

- H13 – Excellent heat resistance for high-temp applications

- S7 – High impact resistance

- 420 Stainless – For corrosion resistance

Aluminum: Used for prototype molds or low-volume production. Advantages include faster machining and better heat dissipation, though it wears faster than steel.

Copper Alloys: Sometimes used for inserts to improve heat transfer in critical areas of the mold.

Beryllium Copper: Combines excellent thermal conductivity with good strength, often used in high-heat areas of molds.

The material selection process also considers the plastic or metal that will be molded. For example, abrasive materials like glass-filled resins require harder mold steels to resist wear. A full service provider will analyze all these factors to recommend the optimal material.

Surface treatments like nitriding or chrome plating can further enhance mold life. These are often applied after machining but before the mold goes into production.

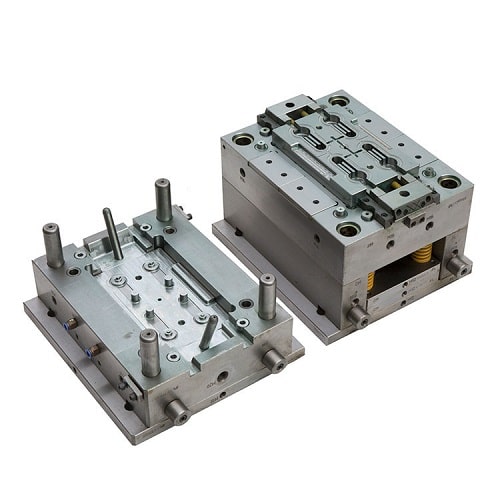

Mold Fabrication Process

Once the design is finalized and materials selected, the actual mold fabrication begins. This is where the digital design becomes a physical tool capable of producing thousands or millions of parts.

The fabrication process typically follows these stages:

- Rough Machining: Removing large amounts of material to create the basic mold shape

- Semi-Finishing: More precise machining to approach final dimensions

- Heat Treatment: For steel molds to achieve proper hardness

- Finishing: Achieving final dimensions and surface finishes

- Detail Work: Adding textures, engraving, or special features

- Assembly: Putting together all mold components

Modern mold shops use advanced CNC (Computer Numerical Control) machines that can automatically follow the CAD model’s instructions with micron-level precision. Five-axis CNC machines are particularly valuable for complex mold geometries.

Electrical Discharge Machining (EDM) is another critical technology, especially for creating intricate details or hard-to-machine features. The EDM process uses electrical sparks to erode metal precisely without physical contact.

Throughout fabrication, quality checks ensure dimensions stay within tolerance. Coordinate Measuring Machines (CMM) and optical comparators verify critical features before proceeding to the next stage.

Precision Machining Techniques

Full service mold makers employ various precision machining methods to create molds with the required accuracy and surface finish. Each technique has specific advantages for different aspects of mold making.

CNC Milling: The workhorse of mold machining, using rotating cutting tools to remove material. Modern CNC mills can achieve tolerances within 0.001 inches (0.025 mm) or better.

CNC Turning: Primarily for cylindrical mold components like cores or ejector pins. The workpiece rotates while a stationary tool cuts.

EDM (Electrical Discharge Machining): Particularly useful for:

- Hardened steels that are difficult to cut conventionally

- Complex geometries with deep cavities

- Sharp internal corners

Wire EDM: A variation that uses a thin wire as the electrode, excellent for cutting intricate profiles and tight radii.

High-Speed Machining: Uses specialized tooling and spindle speeds up to 50,000 RPM to achieve excellent surface finishes while maintaining productivity.

The choice of machining technique depends on factors like material hardness, feature complexity, required surface finish, and production timeline. Full service providers optimize the process by combining these methods strategically.

For example, they might use conventional CNC milling for most of the mold, switch to EDM for delicate details, then apply high-speed machining for critical sealing surfaces. This multi-process approach ensures both efficiency and quality.

Finishing and Polishing Processes

After machining, molds undergo various finishing processes that significantly impact the quality of molded parts and the mold’s service life. These steps transform a machined block into a production-ready tool.

Hand Polishing: Skilled technicians use progressively finer abrasives to achieve the desired surface finish. The level of polish depends on the part requirements:

- SPI A1 (Diamond finish) – For optical clarity

- SPI B1 (600 grit) – High-gloss surfaces

- SPI C1 (400 grit) – General purpose

Texturing: Applying specific surface patterns through chemical etching or laser texturing. Common textures include:

- Leather grain

- Matte finishes

- Custom logos or patterns

Coating: Special coatings can enhance performance:

- Chromium plating for wear resistance

- Nickel plating for corrosion protection

- DLC (Diamond-Like Carbon) for reduced friction

Proper finishing is especially critical for molds producing visible parts or components requiring specific surface properties. The finish affects both appearance and functionality, influencing factors like part release, friction, and light reflection.

Full service providers often have in-house finishing departments with specialists trained in various techniques. This ensures consistent quality and faster turnaround compared to outsourcing these critical steps.

Testing and Validation

Before a mold enters full production, rigorous testing ensures it will perform as expected. This validation phase identifies any issues that need correction before committing to mass production.

First Article Inspection: The initial parts from the mold are carefully measured against design specifications using tools like:

- Coordinate Measuring Machines (CMM)

- Optical comparators

- Laser scanners

- Functional gauges

Process Validation: Verifying that the molding process can consistently produce quality parts. This includes:

- Establishing process parameters (temperature, pressure, cycle time)

- Conducting capability studies

- Performing destructive testing if required

Durability Testing: For high-volume production molds, accelerated life testing may be conducted to predict maintenance needs and total lifespan.

Any issues discovered during testing are addressed through mold modifications. Full service providers benefit from having all capabilities in-house, allowing quick iterations between testing and adjustments.

For medical or automotive applications, validation may include formal documentation like PPAP (Production Part Approval Process) to meet industry standards. This thorough approach prevents costly problems in production.

Production Integration

Full service mold making often extends beyond tool creation to include production support. This integration ensures smooth transition from prototype to mass production.

Process Optimization: Fine-tuning injection parameters for:

- Optimal cycle time

- Material usage efficiency

- Energy consumption

- Part quality consistency

Automation Integration: Implementing robotics for:

- Part removal

- Insert loading

- In-process inspection

Quality Systems: Establishing procedures for:

- Statistical process control

- Regular mold maintenance

- Continuous improvement

Many full service providers offer production monitoring systems that track key metrics in real-time, allowing immediate adjustments if parameters drift out of specification.

This production support is particularly valuable for companies without extensive molding experience. The mold maker’s expertise helps avoid common pitfalls and ensures the mold performs as intended throughout its lifespan.

Benefits of Full Service Mold Making

Choosing a full service mold maker offers numerous advantages over working with multiple specialized vendors. These benefits impact quality, cost, and time-to-market.

Single Point of Responsibility: One vendor handles all aspects, simplifying communication and accountability. Issues can be resolved quickly without finger-pointing between different suppliers.

Faster Turnaround: Integrated processes eliminate delays between stages. Design changes can be implemented immediately without waiting for external vendors.

Cost Efficiency: While hourly rates might be higher, the total project cost is often lower due to:

- Reduced coordination overhead

- Fewer mistakes from miscommunication

- Optimized workflows

Better Quality Control: Consistent standards across all process stages. The team that designed the mold also builds and tests it, ensuring intent is maintained.

Technical Synergy: Designers work directly with machinists, creating designs that are both functional and manufacturable. This collaboration often leads to innovative solutions.

For companies looking to bring new products to market quickly and reliably, these benefits make full service mold making an attractive option. The initial investment in a quality mold pays dividends throughout the product lifecycle.

Frequently Asked Questions

Q: How long does full service mold making typically take?

A: The timeline varies based on complexity, but a standard injection mold might take 8-12 weeks from design to production-ready. Simple molds can be completed in 4-6 weeks, while highly complex tools may require 16+ weeks. Factors affecting timeline include mold size, complexity, material selection, and required surface finishes.

Q: What’s the difference between prototype molds and production molds?

A: Prototype molds are designed for limited runs (50-1,000 parts) and often use softer materials like aluminum to reduce cost and lead time. Production molds are built for durability (100,000+ cycles) using hardened steels with more robust cooling and ejection systems. The choice depends on your development stage and volume needs.

Q: How do I choose between aluminum and steel for my mold?

A: Aluminum is best for prototypes or low-volume production (under 10,000 parts) where cost and speed are priorities. Steel is necessary for high-volume production due to its durability. Other factors include part material (abrasive materials require steel), required tolerances (steel holds dimensions longer), and surface finish needs.

Q: What file formats do mold makers need for design?

A: Most mold makers prefer 3D CAD files in native formats like STEP, IGES, or Parasolid. Common software formats include:

AutoCAD (.dwg, .dxf)

Inventor (.ipt, .iam)

Pro/ENGINEER (.prt, .asm)

CATIA (.catpart, .catproduct)

2D drawings in PDF format are also helpful for critical dimensions and tolerances.

Q: How can I reduce mold making costs?

A: Several design strategies can lower costs:

- Minimize undercuts and complex geometries

- Standardize wall thicknesses

- Use draft angles (1-2° minimum)

- Consider family molds for small parts

- Opt for multi-cavity molds only when volumes justify the higher initial cost

Early consultation with your mold maker can identify cost-saving opportunities without compromising part function.

Conclusion

Full service mold making represents the pinnacle of manufacturing efficiency, combining design expertise, precision engineering, and production knowledge into a seamless process. From initial concept to final production, this comprehensive approach ensures quality, reduces time-to-market, and ultimately delivers better results for your products.

As we’ve explored, the process involves numerous specialized steps – each critical to creating molds that produce consistent, high-quality parts. The advantages of working with a full service provider include better communication, faster problem resolution, and the technical synergy that comes from having all capabilities under one roof.

Whether you’re developing a new product or optimizing an existing one, partnering with an experienced full service mold maker can make the difference between a good outcome and a great one. Their expertise can help navigate material selections, design challenges, and production considerations that might not be apparent at first glance.

For more insights into manufacturing processes, check out our related articles on injection molding techniques and design for manufacturability.

Need Precision CNC Machining for Your Mold Components?

We specialize in custom CNC machining of mold inserts, slide cores, ejector plates, mold bases, and lifters

all made to your exact drawings and specifications.

👉 Let’s Build Your Next Project Together!

Tell us your needs and upload your drawings — we’ll get back within 24 hours.