Catalog

Tags

Unlocking Plastic Molds: A Comprehensive Guide to Types and Customs Classification

Meta Description: Confused about plastic molds and their customs classification? This in-depth guide explains the six major types of plastic molds, their forming processes, and provides a detailed breakdown of their corresponding HS codes for seamless import and declaration.

Molds are essential tools in modern industry, playing a critical role in the production of countless industrial goods. As a key global manufacturing hub, China has seen a growing demand for mold imports, making it crucial for businesses to understand mold types and their proper customs classifications.

While there are many types of molds, such as those for rubber, metal, glass, and composites, this article focuses on the most common category: plastic molds. We’ll break down the different types of plastic molds, the processes they use, and their specific customs classifications, making it easier for you to navigate the complexities of import declarations.

Table of Contents

Unlocking Plastic Molds: A Comprehensive Guide to Types and Customs Classification

The Six Major Types of Plastic Molds and Their Forming Processes

Plastic Injection Molds

Plastic Compression Molds

Plastic Extrusion Molds

Plastic Blow Molds

Plastic Thermoforming (Vacuum Forming) Molds

High-Foam Polystyrene Molds

Customs Declaration Tips

Frequently Asked Questions (FAQ)

The Six Major Types of Plastic Molds and Their Forming Processes

Plastic forming methods are broadly categorized into melt forming and solid-state forming. Melt forming heats plastic to a molten state for processing, while solid-state forming keeps the plastic in a solid state below its melting temperature. Based on these methods, we can identify six primary types of plastic molds.

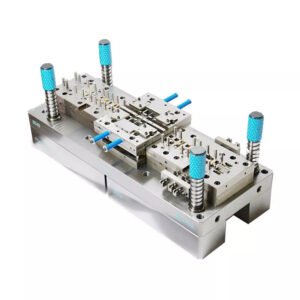

1. Plastic Injection Molds

Forming Process: Melt forming. Molten thermoplastic is injected at high pressure into a mold cavity, where it cools and solidifies to create the final part.

Key Applications: Manufacturing a wide range of products, from household goods and intricate mechanical parts to electronic housings and automotive components.

Structural Features: Composed of multiple parts, including molding components, a gating system, an ejection mechanism, and a temperature control system.

Customs Classification: 8480.7100

2. Plastic Compression Molds

Forming Process: Melt forming. Primarily used for thermosetting plastics, this process involves placing a measured amount of plastic powder into a heated mold cavity. Under high heat and pressure, the plastic softens and then solidifies into the desired shape.

Key Applications: Encapsulating electronic components, producing high-quality resin lenses, and forming specialized parts from hard-to-melt plastics like PTFE.

Structural Features: Consists of a cavity, a loading chamber, a guiding mechanism, and a heating system.

Customs Classification: 8480.7100

3. Plastic Extrusion Molds

Forming Process: Melt forming. Also known as an extrusion die head, this mold creates continuous-shaped plastic products. Solid plastic is melted and pushed through a die to form a continuous cross-section.

Key Applications: Used to produce pipes, rods, sheets, films, wires, cables, and various profiles.

Structural Features: Structurally distinct from injection and compression molds, designed to create a continuous output.

Customs Classification: 8480.7900

4. Plastic Blow Molds

Forming Process: Melt forming. A molten plastic parison (a tube-like plastic piece) is placed in the mold, and compressed air is blown into it, forcing the plastic to expand and conform to the shape of the mold cavity.

Key Applications: Manufacturing hollow containers like bottles for beverages, cosmetics, and other packaging.

Structural Features: Typically simpler in design, often made from carbon steel.

Customs Classification: 8480.7900

5. Plastic Thermoforming (Vacuum Forming) Molds

Forming Process: Solid-state forming. A heated plastic sheet is draped over or into a mold. A vacuum or compressed air then forces the softened sheet to conform to the mold’s shape.

Key Applications: Producing packaging for daily necessities, food, and toys.

Structural Features: Molds are simple due to low forming pressure and are often made from cast aluminum or non-metallic materials.

Customs Classification: 8480.7900

6. High-Foam Polystyrene Molds

Forming Process: Steam forming. Expandable polystyrene beads are placed in a mold and steamed, causing them to expand and fuse into the desired foam plastic shape.

Key Applications: Creating packaging for industrial products.

Structural Features: Can range from simple manual molds to hydraulic press molds. Materials include cast aluminum, stainless steel, and bronze.

Customs Classification: 8480.7900

Customs Declaration Tips

The customs classification of molds primarily falls under headings 84.80 and 82.07. For plastic molds, the main distinction is between two subheadings:

HS Code 8480.7100: This includes injection and compression molds. These molds are typically more complex and are used to create precise plastic parts.

HS Code 8480.7900: This covers extrusion, blow, thermoforming, and high-foam polystyrene molds. These molds are used for creating continuous, hollow, or foamed plastic products.

To ensure a smooth customs clearance process, it’s essential to declare your molds using the correct, standardized product names. Accurate classification will help you avoid delays and potential penalties, ensuring your imports are both efficient and compliant.

Frequently Asked Questions (FAQ)

Q1: Why is correct mold classification so important?

A1: Correct classification is crucial for seamless import customs clearance. An incorrect classification can lead to inaccurate declarations, customs delays, and even fines. Knowing the right customs classification helps your business make compliant declarations, saving both time and money.

Q2: Both injection molds and compression molds fall under HS Code 8480.7100. What’s the main difference between them?

A2: The main difference lies in their forming process and the types of plastic they handle. Injection molds are primarily for thermoplastics, which are melted and injected into a mold. Compression molds are mainly for thermosetting plastics, which are solidified under high heat and pressure in the mold.

Q3: Why is an extrusion mold classified under HS Code 8480.7900?

A3: Extrusion molds differ significantly in their working principle from injection and compression molds. They’re designed to produce continuous plastic products like pipes and sheets. This distinction in function and structure places them in a separate category under HS Code 8480.7900, along with other non-injection and non-compression plastic molds.

Q4: What should I do if I’m unsure about my mold’s classification?

A4: If you’re uncertain about your mold’s classification, it’s best to consult a professional customs broker or a customs consultant. Providing detailed information about the mold’s use, forming process, and structural photos can help them make an accurate determination. When declaring, always use a detailed description and a standardized product name to ensure accuracy.

Need Precision CNC Machining for Your Mold Components?

We specialize in custom CNC machining of mold inserts, slide cores, ejector plates, mold bases, and lifters

all made to your exact drawings and specifications.

👉 Let’s Build Your Next Project Together!

Tell us your needs and upload your drawings — we’ll get back within 24 hours.