Catalog

Tags

How to Grow Your CNC Machining Business in 2025: 10 Proven Strategies

The CNC machining industry is projected to reach $115 billion by 2025, creating immense opportunities for shop owners ready to adapt. Whether you’re running a job shop or production facility, this guide reveals actionable strategies to scale your operations, boost efficiency, and outpace competitors in the coming year.

Table of Contents

- 1. Embrace Smart Automation

- 2. Diversify Your Service Offerings

- 3. Strengthen Your Digital Presence

- 4. Optimize Supply Chain Relationships

- 5. Invest in Workforce Training

- 6. Implement Sustainable Practices

- 7. Leverage Data Analytics

- 8. Dominate a Niche Market

- 9. Rethink Your Pricing Strategy

- 10. Build Strategic Partnerships

- FAQs

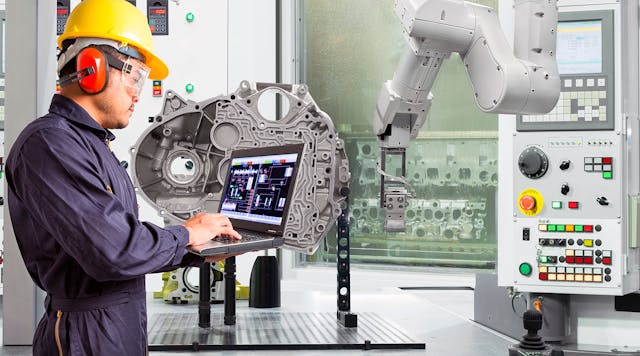

1. Embrace Smart Automation

The automation adoption rate in machining has tripled since 2020. Consider these implementations:

- Robotic part loading/unloading: Increases machine uptime by 40%

- Lights-out manufacturing: Run operations 24/7 without human oversight

- Automated inspection: Implement machine vision systems for quality control

Example: A Midwest job shop reduced labor costs by 28% after installing pallet changers on their VMCs.

2. Diversify Your Service Offerings

Expand beyond traditional milling/turning services:

- Additive manufacturing (hybrid machines)

- Swiss-style precision turning

- Micro-machining for medical devices

Read our guide on profitable CNC service expansions.

3. Strengthen Your Digital Presence

In the CNC machining business, a strong online presence is crucial—87% of industrial buyers search online before contacting suppliers. To capture their attention, ensure you have these essential components:

Professional Website – Showcase your machining capabilities, materials, tolerances, and industries served.

Search Engine Optimization (SEO) – Make it easy for buyers to find you on Google.

High-Quality Content – Use videos, photos, and case studies to prove your expertise.

Online Contact Channels – Make it simple for prospects to request quotes or ask questions.

Social Media – Share finished projects and behind-the-scenes processes to build credibility.

4. Optimize Supply Chain Relationships

Develop partnerships with:

- Local material suppliers

- Cutting tool manufacturers

- Logistics providers

5. Invest in Workforce Training

Key training areas for 2025:

- CAM software updates

- IoT machine monitoring

- Metrology advancements

6. Implement Sustainable Practices

Eco-friendly measures that reduce costs:

- Coolant recycling systems

- Energy-efficient spindle motors

- Scrap metal monetization

7. Leverage Data Analytics

Track these KPIs religiously:

- Machine utilization rate

- Setup-to-run time ratio

- Tool life variance

8. Dominate a Niche Market

Specialization examples:

- Aerospace fasteners

- EV battery components

- Semiconductor fixtures

9. Rethink Your Pricing Strategy

Move beyond hourly rates:

- Value-based pricing

- Subscription models

- Bundled services

10. Build Strategic Partnerships

Collaborate with:

- Engineering firms

- Prototype labs

- Industrial designers

Frequently Asked Questions

What’s the biggest growth opportunity for CNC shops in 2025?

The aerospace and medical sectors will see 12-15% annual growth. Investing in AS9100 or ISO 13485 certifications now positions you for these contracts.

How much should I budget for automation?

Most shops allocate 7-15% of annual revenue. ROI typically occurs in 18-36 months through labor savings and increased throughput.

What marketing channels work best for CNC businesses?

LinkedIn generates 3x more leads than other platforms for industrial services. Combine this with SEO-optimized case studies showcasing complex parts you’ve manufactured.

Conclusion

Growing your CNC machining business in 2025 requires a balanced approach of technological adoption, workforce development, and strategic marketing. By implementing even 3-5 of these strategies, you’ll position your shop for sustainable growth in an increasingly competitive market.

For deeper insights, read our companion piece: Advanced CNC Shop Management Techniques for 2025.

Need Precision CNC Machining for Your Mold Components?

We specialize in custom CNC machining of mold inserts, slide cores, ejector plates, mold bases, and lifters

all made to your exact drawings and specifications.

👉 Let’s Build Your Next Project Together!

Tell us your needs and upload your drawings — we’ll get back within 24 hours.