Catalog

Tags

General Machining: The Backbone of Modern Manufacturing

TL;DR: General machining is a fundamental manufacturing process that shapes raw materials into precise components using cutting, drilling, and milling. It’s essential for industries like aerospace, automotive, and medical devices due to its versatility, precision, and scalability.

How General Machining Works

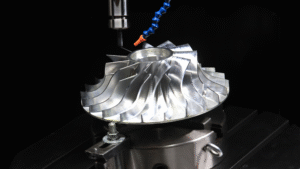

General machining removes material from a workpiece (metal, plastic, or composite) using tools like lathes, mills, or grinders. Computer Numerical Control (CNC) machines automate the process for high accuracy and repeatability. Key principles include:

- Subtractive Manufacturing: Material is cut away to achieve the desired shape.

- Precision Tolerances: Achieves tight tolerances (up to ±0.001 inches).

- Toolpath Optimization: CNC programs dictate tool movements for efficiency.

Types, Processes & Materials

| Process | Description | Common Materials |

| Milling | Rotating tools cut material horizontally/vertically. | Aluminum, Steel, Plastics |

| Turning | Workpiece rotates while a tool shapes it (lathes). | Brass, Titanium, Nylon |

| Drilling | Creates holes with drill bits. | Composites, Stainless Steel |

| Grinding | Abrasive wheels refine surfaces. | Ceramics, Hardened Metals |

Advantages & Best Use Cases

- High Precision: Ideal for complex geometries (e.g., engine parts).

- Material Flexibility: Works with metals, plastics, and more.

- Scalability: Suitable for prototypes and mass production.

Top Industries: Aerospace (turbine blades), Automotive (transmission parts), Medical (implants).

Real-World Applications

Boeing uses CNC machining for aircraft components, while Tesla relies on it for custom battery housings. Small businesses leverage desktop CNC mills for rapid prototyping.

FAQ

- Q: How does CNC improve machining?

A: CNC automates toolpaths for faster, error-free production. - Q: What’s the cost range?

A: $50–$500/hour, depending on complexity. - Q: Can it handle brittle materials?

A: Yes, with specialized tools (e.g., diamond cutters for ceramics).

Ready to Start Your Project?

Partner with a certified machining service or explore CNC training courses to bring your designs to life.

Final Thought: General machining bridges innovation and production, enabling everything from micro-devices to industrial machinery.

🏁 Conclusion: Combining Precision for Perfect Results

At Ruixin Mold, we don’t just perform machining—we optimize it. By combining turning, milling, and drilling in a single workflow, we ensure your parts are produced with maximum precision, consistency, and efficiency.

Whether you’re building custom mold components, automotive parts, or high-tolerance assemblies, we deliver reliable CNC machining solutions — from prototype to production.

📩 Ready to Start Your Project?

Partner with Ruixin Mold for expert CNC machining services from China.

👉 Visit www.dgruixinmold.com or contact us for a free quote today.

Need Precision CNC Machining for Your Mold Components?

We specialize in custom CNC machining of mold inserts, slide cores, ejector plates, mold bases, and lifters

all made to your exact drawings and specifications.

👉 Let’s Build Your Next Project Together!

Tell us your needs and upload your drawings — we’ll get back within 24 hours.