Catalog

Tags

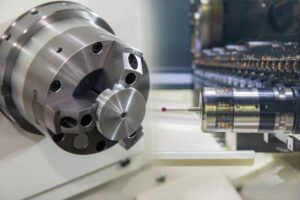

CNC Machining Workholding: Styles, Techniques, and Key Considerations

TL;DR: CNC machining workholding refers to the methods and devices used to securely hold a workpiece during machining. Common styles include vises, clamps, chucks, and fixtures, each suited for specific applications. Key considerations include material, precision, and production volume.

How CNC Machining Workholding Works

Workholding in CNC machining ensures the workpiece remains stable and accurately positioned during cutting, drilling, or milling. Stability is critical to achieving tight tolerances and preventing vibrations that can affect surface finish and tool life. The choice of workholding depends on factors like part geometry, machining forces, and production speed.

Types of CNC Workholding (With Comparison Table)

| Workholding Type | Best For | Materials Supported |

|---|---|---|

| Mechanical Vises | High precision, repetitive tasks | Metals, plastics, composites |

| Hydraulic Clamps | Heavy-duty machining | Steel, titanium, alloys |

| Vacuum Chucks | Thin or delicate parts | Aluminum, plastics, PCB |

| Custom Fixtures | Complex geometries | All materials |

- Mechanical Vises: Common for milling, provide strong grip.

- Magnetic Chucks: Ideal for ferrous metals, quick setup.

- Collet Chucks: Used in high-speed CNC turning.

- Modular Fixtures: Flexible for small-batch production.

Advantages and Best Use Cases

Advantages:

- Improves machining accuracy and repeatability.

- Reduces setup time for mass production.

- Minimizes workpiece deformation.

Best Use Cases:

- Vises: Milling flat parts.

- Vacuum Chucks: Machining thin sheets.

- Custom Fixtures: Aerospace components.

Real-World Applications

Example: Haas Automation uses hydraulic clamping systems for high-volume automotive part production, ensuring consistent precision. Another case is Boeing, which employs custom modular fixtures for complex aircraft components.

FAQ

- Q: How do I choose the right workholding?

A: Consider part size, material, and required tolerances. - Q: Can one workholding solution fit all needs?

A: No, specialized fixtures often improve efficiency. - Q: Does workholding affect CNC tool life?

A: Yes, poor workholding increases vibration and wear.

Need Expert CNC Workholding Solutions?

Optimize your CNC machining process with the right workholding. Contact our team for a customized recommendation based on your project requirements.

Summary: Selecting the proper CNC workholding method improves precision, reduces waste, and enhances productivity. Evaluate your needs based on material, part complexity, and production volume.

Need Precision CNC Machining for Your Mold Components?

We specialize in custom CNC machining of mold inserts, slide cores, ejector plates, mold bases, and lifters

all made to your exact drawings and specifications.

👉 Let’s Build Your Next Project Together!

Tell us your needs and upload your drawings — we’ll get back within 24 hours.