cnc machining parts china

Mold Design Rapid Prototyping CNC Machining One-Stop Solutions · Mold Manufacturing · CNC Maching · Sheet and Tube Fabrication

Materials

CNC machining in China supports a wide variety of materials:

Metals: Aluminum, steel, stainless steel, brass, copper, titanium, magnesium, etc.

Plastics: ABS, POM, PC, Nylon, PP, PVC, PTFE, etc.

Special Alloys: Inconel, Hastelloy, and other high-performance materials for demanding applications.

Production Details

- Capabilities:

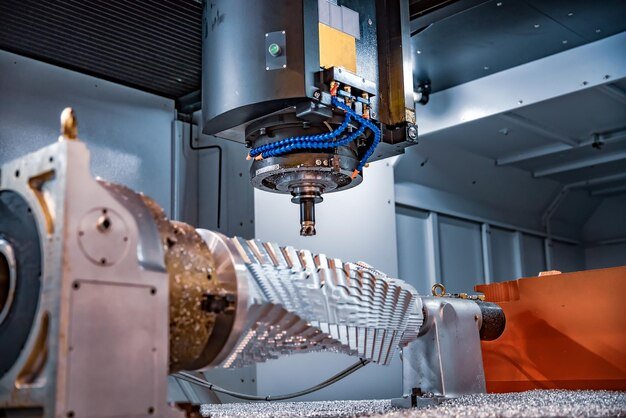

CNC machining in China includes processes such as CNC milling, turning, drilling, grinding, and multi-axis machining to handle complex geometries and tight tolerances. - Equipment:

Factories in China often utilize state-of-the-art machines, including 3-axis, 4-axis, and 5-axis CNC machines, along with advanced automation for high efficiency. - Process Flow:

- Design: Customers provide CAD models or technical drawings.

- Programming: CAM software is used to generate tool paths and machine instructions.

- Machining: High-precision cutting tools shape the material into the desired part.

- Finishing: Surface treatments, deburring, and polishing enhance part quality.

- Inspection: Dimensional accuracy is verified using CMM (Coordinate Measuring Machines) and other tools.

- Lead Times: Fast turnaround times, often as short as a few days for prototypes or small production runs.

Applications

- Aerospace: High-precision components like turbine blades and structural parts.

- Automotive: Engine parts, gearboxes, and prototypes.

- Electronics: Housings, connectors, and small mechanical components.

- Medical Devices: Surgical instruments and diagnostic equipment parts.

- Industrial Machinery: Custom parts for various manufacturing equipment.

Features

- High Precision: Achieves tolerances as tight as ±0.005 mm.

- Cost-Effective: Competitive labor costs and scalable production make China a hub for CNC machining.

- Quick Prototyping: Ideal for rapid prototyping and low-volume production.

- Custom Solutions: Tailored services for diverse industries and specific requirements.

- Advanced Technology: Adoption of Industry 4.0 practices, including automation and IoT integration.

Q: Why is CNC machining in China so popular?

A: China offers a combination of cost efficiency, advanced technology, and large-scale manufacturing capacity, making it a preferred choice for global customers.Q: How do Chinese CNC machining services ensure quality?

A: Quality is ensured through ISO certifications, stringent inspections, and advanced tools like CMM for measurement accuracy.Q: Can CNC machining in China handle complex designs?

A: Yes, with 4-axis and 5-axis machining capabilities, Chinese manufacturers can produce intricate parts with complex geometries.Q: Is it possible to get small production runs or prototypes?

A: Absolutely. Many Chinese CNC suppliers specialize in rapid prototyping and low-volume production while maintaining quality.Q: What industries benefit most from Chinese CNC machining?

A: Industries like automotive, aerospace, electronics, medical, and industrial manufacturing benefit significantly from China’s expertise in CNC machining.

None