Catalog

Tags

When you need to cut incredibly hard materials with extreme precision and create complex shapes that traditional machining simply can’t handle, Wire EDM (Electrical Discharge Machining) is the superior solution. This advanced machining process is a game-changer for industries where accuracy and material integrity are non-negotiable.

Wire EDM is a precise, non-contact machining process that uses a thin, electrically charged brass wire and deionized water to cut through conductive materials with exceptional accuracy. Its key advantages include the ability to machine extremely hard materials, achieve tight tolerances without distortion, and produce intricate, delicate parts that other methods cannot.

How Does Wire EDM Machining Work?

Think of Wire EDM as precision erosion. It doesn’t cut material with physical force; instead, it uses controlled electrical sparks. Here’s the basic principle:

- A thin, continuously fed brass wire acts as one electrode.

- The conductive workpiece acts as the other electrode.

- Both are submerged in a tank of deionized water, which acts as an insulator and coolant.

- A powerful electrical charge is applied to the wire, creating a series of rapid, controlled sparks between the wire and the workpiece.

- These sparks generate intense heat (up to 20,000°F), vaporizing microscopic particles of the material.

- The deionized water flushes away the eroded particles and prevents excessive heat.

- The wire is guided along a pre-programmed CNC path, precisely “eroding” the desired shape without ever touching the workpiece.

Types, Processes, and Compatible Materials

Wire EDM isn’t a one-size-fits-all process. Understanding its variations and material compatibility is key to leveraging its advantages.

| Process Type | Key Characteristic | Primary Use Case |

|---|---|---|

| 2-Axis Wire EDM | Cuts in two axes (X and Y). The wire remains vertical. | Standard through-hole cuts, punches, and dies. |

| 4-Axis Wire EDM | Allows the upper wire guide to move independently (U and V axes), tilting the wire. | Tapered cuts, complex contours with draft angles, and clearances. |

Common Wire EDM Materials:

- Metals: Tool steel, stainless steel, aluminum, titanium, inconel, hastelloy, carbide, brass, copper.

- Key Requirement: The material must be electrically conductive.

Key Advantages and Ideal Applications

- Machines Any Conductive Material: Regardless of hardness. Since it’s a thermal process, machining hardened tool steel is as easy as machining aluminum.

- Exceptional Precision and Tolerances: Achieves tolerances within ±0.0001″ (±0.0025mm) and surface finishes as fine as 5 Ra µin.

- Zero Mechanical Stress: The non-contact nature means there is no tool pressure, eliminating the risk of part distortion—crucial for thin, delicate, or fragile components.

- Intricate Geometry and Sharp Corners: Perfect for producing complex shapes, fine details, and internal sharp corners that milling cutters cannot create.

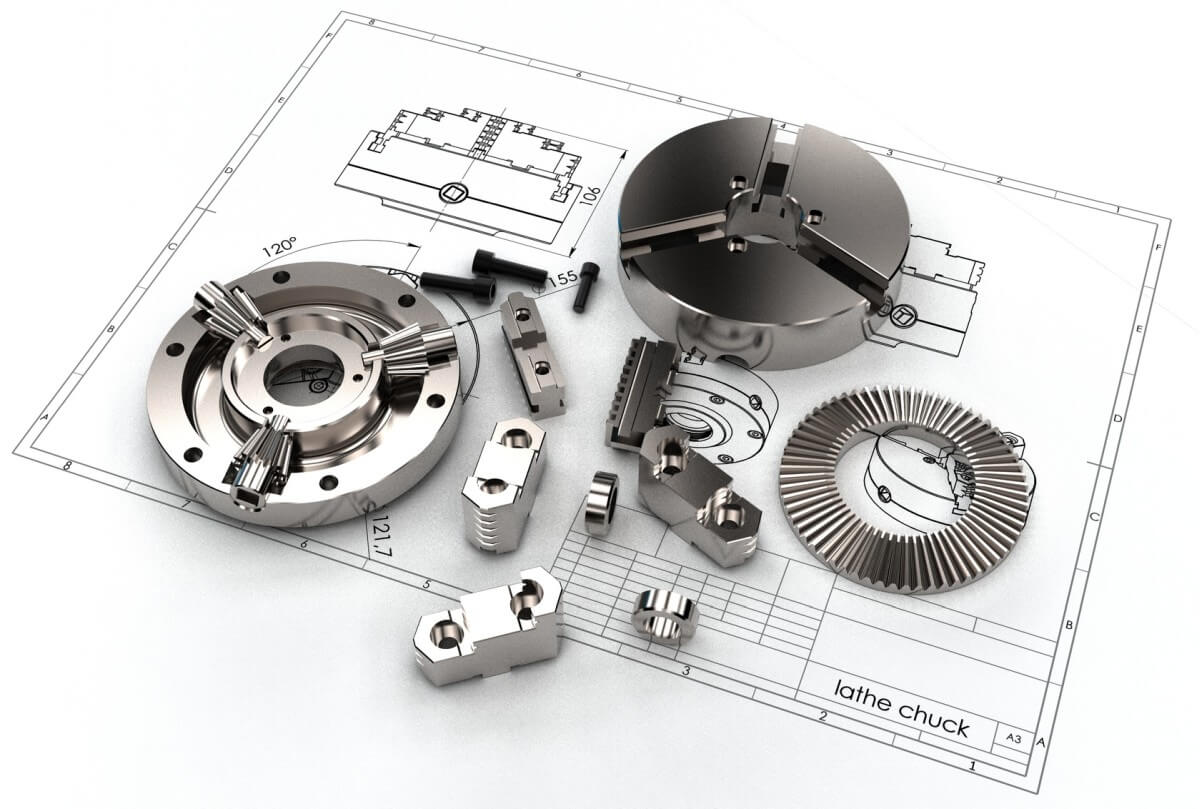

Ideal Use Cases: Injection molds and stamping dies, aerospace and medical components, prototypes, and gears.

Wire EDM in Action: Real-World Case Study

Company: A leading aerospace manufacturer.

Challenge: Produce a critical turbine engine component from a single piece of high-temperature Inconel alloy. The part required intricate cooling channels with extreme dimensional accuracy and a flawless surface finish to withstand intense heat and stress. Traditional machining caused micro-cracks and tool wear, leading to high scrap rates.

Solution: The manufacturer switched to 4-Axis Wire EDM. The process effortlessly cut the hardened Inconel without inducing stress or micro-cracks. The 4-axis capability allowed for the precise creation of tapered cooling channels.

Result: A 40% reduction in production time, a scrap rate near zero, and a component that met all stringent aerospace performance specifications. This highlights how Wire EDM solves problems that are impossible or prohibitively expensive with conventional methods.

Wire EDM FAQ

- Q: How thick of a material can Wire EDM cut?

A: It can cut very thick materials, often up to 12 inches (300mm) or more, depending on the machine. - Q: What is the “recast layer” or “white layer”?

A: It’s a thin, hardened layer on the cut surface caused by the rapid heating and cooling. For most applications, it is insignificant, but it can be removed with secondary finishing if necessary. - Q: Is Wire EDM fast?

A: It’s not typically a high-speed process. Its value lies in precision, not speed. Cutting rates are measured in square inches per hour. - Q: Can it create blind holes?

A: No. Standard Wire EDM requires a starter hole to thread the wire through, so it can only cut through-holes.

Ready to Harness the Power of Precision?

Do you have a challenging project involving hard materials, complex geometries, or ultra-tight tolerances? Wire EDM might be the perfect solution. Contact our machining experts today for a free design review and quote. Let’s turn your most complex designs into reality.

Wire EDM machining is the undisputed champion of precision manufacturing for conductive materials. Its ability to cut intricate shapes in ultra-hard substances without contact or distortion makes it an indispensable technology for the aerospace, medical, and tooling industries. When your project demands absolute accuracy, Wire EDM delivers.

Need Precision CNC Machining for Your Mold Components?

We specialize in custom CNC machining of mold inserts, slide cores, ejector plates, mold bases, and lifters

all made to your exact drawings and specifications.

👉 Let’s Build Your Next Project Together!

Tell us your needs and upload your drawings — we’ll get back within 24 hours.