Catalog

Tags

How Does Sinker EDM Work? The Complete Guide to Electrical Discharge Machining

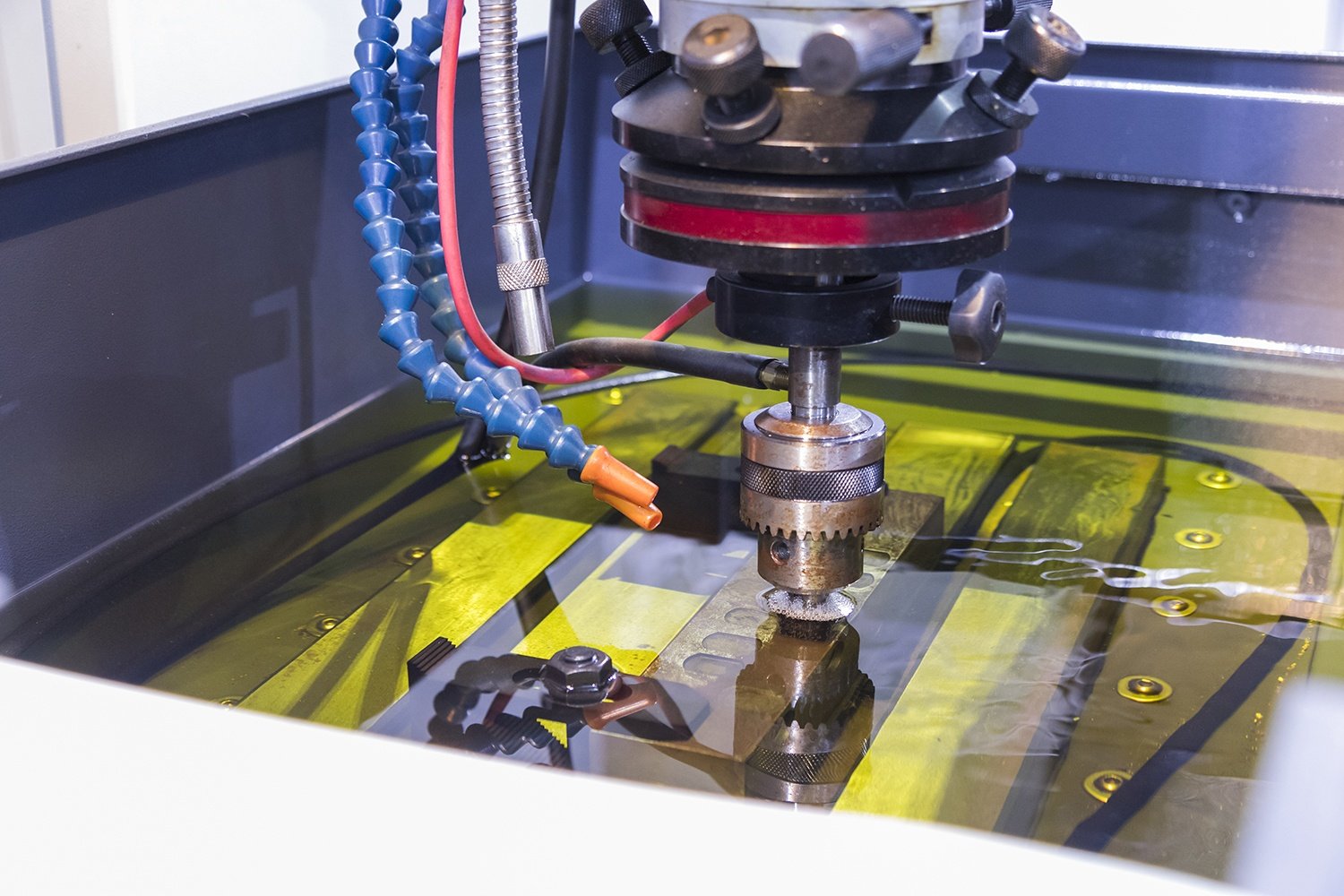

In the world of precision manufacturing, sinker EDM (Electrical Discharge Machining) stands out as a revolutionary technology capable of creating complex shapes in extremely hard materials with micron-level accuracy. But how exactly does this fascinating process work? This comprehensive guide will explain the science behind sinker EDM, its key components, working principles, and why it’s become indispensable in industries ranging from aerospace to medical device manufacturing.

Unlike conventional machining methods that rely on physical cutting tools, sinker EDM uses controlled electrical sparks to erode material, allowing it to machine materials that would be impossible to cut with traditional methods. Whether you’re a manufacturing professional looking to deepen your understanding or simply curious about advanced machining technologies, this article will illuminate the inner workings of sinker EDM.

Table of Contents

What is Sinker EDM?

Sinker EDM, also known as ram EDM, die-sinking EDM, or conventional EDM, is a non-traditional machining process that uses electrical discharges (sparks) to remove material from a workpiece. The name “sinker” comes from the process where an electrode “sinks” into the workpiece, creating a negative impression of its shape.

This process was first observed in the 1770s but wasn’t developed into a practical manufacturing technique until the 1940s. Today, modern CNC-controlled sinker EDM machines can achieve tolerances as tight as ±0.005 mm (±0.0002 inches), making them invaluable for precision applications.

Unlike wire EDM which uses a thin wire as an electrode, sinker EDM uses custom-shaped electrodes (typically made of graphite or copper) that are precisely machined to match the desired cavity shape. This makes it particularly useful for creating complex 3D geometries, molds, and dies that would be difficult or impossible to produce with conventional machining.

The process is especially valuable for machining hardened steels, titanium, carbides, and other materials that are challenging to cut with traditional methods. Because there’s no physical contact between tool and workpiece, sinker EDM can machine delicate features without introducing mechanical stresses.

Key Components of a Sinker EDM Machine

A typical sinker EDM system consists of several critical components that work together to create precise electrical discharges and control the machining process:

1. Power Supply: Generates pulsed DC current that creates the sparks between electrode and workpiece. Modern machines use adaptive power supplies that can adjust parameters in real-time for optimal machining.

2. Electrode: The tool (usually graphite or copper) that is shaped to form the desired cavity. The electrode wears during the process and may need to be replaced or re-machined for high-precision work.

3. Workpiece: The material being machined, which must be electrically conductive. Common materials include steel, titanium, tungsten carbide, and conductive ceramics.

4. Dielectric System: Includes a reservoir, pump, filtration system, and nozzles to deliver dielectric fluid (typically hydrocarbon oil) to the machining area. This fluid serves multiple critical functions we’ll explore later.

5. Servo Control System: Maintains the precise gap (typically 0.01-0.05 mm) between electrode and workpiece by constantly adjusting the position based on spark conditions.

6. CNC Control: Modern machines use computer numerical control to manage electrode movement, machining parameters, and often include advanced features like adaptive control and process monitoring.

The Working Principle of Sinker EDM

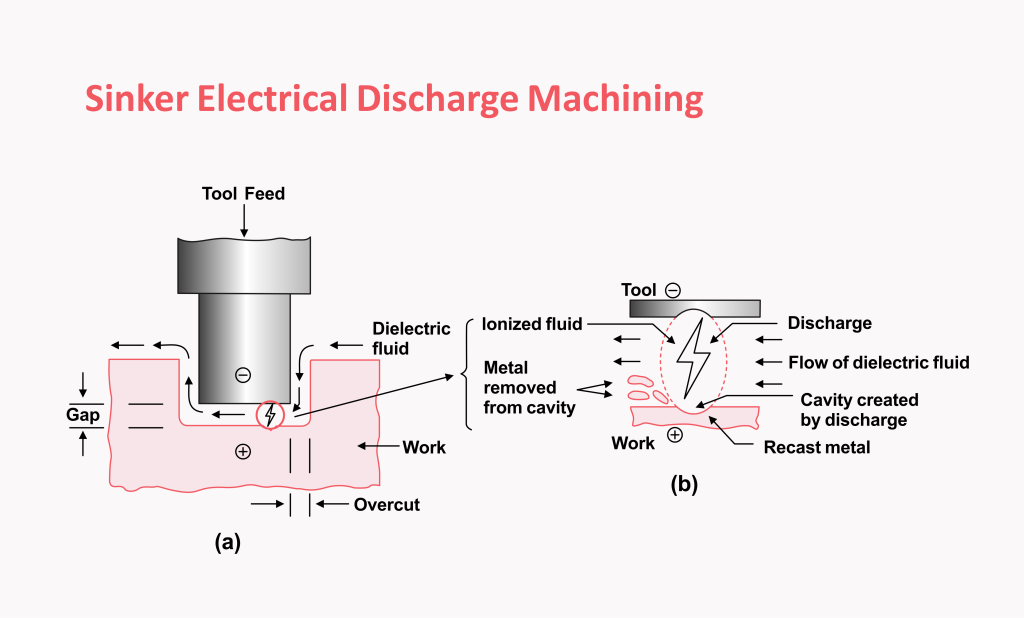

The fundamental principle behind sinker EDM is surprisingly simple: controlled electrical sparks erode material from both the electrode and workpiece. Here’s a step-by-step breakdown of how the process works:

Step 1: The electrode (shaped to the desired cavity form) is positioned close to the workpiece with a small gap (0.01-0.05 mm) filled with dielectric fluid.

Step 2: The power supply generates a high-frequency pulsed DC voltage (typically 50-300V) between the electrode and workpiece. When the voltage reaches the breakdown point of the dielectric fluid (about 15,000-30,000 V/mm), it ionizes the fluid, creating a conductive plasma channel.

Step 3: A spark jumps across this ionized channel, reaching temperatures of 8,000-12,000°C (14,432-21,632°F) at the point of impact. This intense heat melts and vaporizes microscopic amounts of material from both surfaces.

Step 4: The dielectric fluid then flushes away the eroded particles and cools the area, while also deionizing the gap to prevent continuous arcing.

Step 5: The servo system advances the electrode to maintain the optimal gap distance as material is removed. This cycle repeats thousands to millions of times per second, gradually sinking the electrode shape into the workpiece.

The entire process occurs in a dielectric fluid bath which serves multiple purposes: it acts as an insulator until the breakdown voltage is reached, cools the workpiece, flushes away debris, and helps prevent excessive electrode wear.

Electrode Materials and Design

The choice of electrode material significantly impacts the sinker EDM process’s efficiency, accuracy, and cost. The most common materials are:

Graphite: The most popular choice for most applications due to its excellent machinability, good wear resistance, and high melting point (3,600°C). Graphite electrodes can be easily machined to complex shapes and are relatively inexpensive.

Copper: Offers better surface finish than graphite but wears faster. Often used for fine-detail work or when excellent surface finish is required. Copper tungsten alloys are used for tungsten carbide machining.

Brass: Primarily used for specialized applications like small-hole drilling EDM. It provides stable sparking but has higher wear rates.

Electrode design is a critical factor in sinker EDM. The electrode must account for:

- Overburn (the gap between electrode and final cavity size)

- Expected wear rates during machining

- Multiple electrodes may be needed for roughing and finishing passes

- Venting channels may be required for deep cavities to allow dielectric flow

Modern CAD/CAM systems can automatically generate electrode designs that account for these factors, significantly reducing setup time and improving accuracy.

The Role of Dielectric Fluid

The dielectric fluid in sinker EDM serves four critical functions:

1. Insulation: Acts as an insulator between electrode and workpiece until the breakdown voltage is reached, allowing controlled sparking rather than continuous arcing.

2. Cooling: Rapidly cools the extremely hot spark zone to prevent thermal damage to both workpiece and electrode.

3. Flushing: Carries away eroded particles (called “swarf”) from the machining gap. Proper flushing is essential to prevent arcing on accumulated debris.

4. Deionization: After each spark, the fluid must quickly deionize to restore its insulating properties for the next pulse.

The most common dielectric fluids are hydrocarbon oils, which offer good insulating properties and high flash points. For some applications, deionized water or special synthetic fluids may be used. The fluid is continuously filtered to remove particles and maintain consistent machining performance.

Advanced machines often have multiple flushing options:

- Pressure flushing through the electrode

- Suction flushing

- Jet flushing

- Orbital flushing for complex cavities

Process Control and Parameters

Modern sinker EDM machines offer extensive control over numerous parameters that affect machining speed, surface finish, electrode wear, and accuracy:

Current (Amperage): Higher currents remove material faster but create larger craters and rougher surfaces. Roughing operations typically use 20-50A, while finishing might use 1-5A.

Pulse Duration (On-time): Longer pulses allow more energy to be delivered per spark, increasing removal rate but also increasing crater size. Typical range is 1-2000 microseconds.

Pulse Interval (Off-time): The time between sparks allows dielectric fluid to deionize and flush debris. Insufficient off-time can lead to arcing.

Polarity: Most sinker EDM uses positive polarity (electrode positive, workpiece negative) which generally results in better electrode wear characteristics.

Servo Control: The system constantly monitors spark conditions and adjusts the gap to maintain optimal machining. Advanced systems can detect different machining conditions and automatically adjust parameters.

Modern CNC sinker EDMs often feature:

- Adaptive control systems that optimize parameters in real-time

- Multiple machining passes with different parameters for roughing and finishing

- Orbital machining strategies that move the electrode in controlled patterns to improve flushing and accuracy

- Automated electrode changers for complex jobs requiring multiple electrodes

Advantages of Sinker EDM

Sinker EDM offers numerous advantages that make it indispensable for many manufacturing applications:

1. Machining Hard Materials: Can machine hardened steels, carbides, and exotic alloys that would be difficult or impossible to cut with conventional methods. The workpiece hardness doesn’t affect the EDM process.

2. Complex Geometries: Capable of producing intricate cavities, sharp internal corners, and complex 3D shapes that would be challenging with milling or grinding.

3. No Mechanical Forces: Since there’s no physical contact between tool and workpiece, there’s no risk of distorting delicate parts or tools breaking during machining.

4. Excellent Surface Finish: Can achieve surface finishes down to Ra 0.1 μm (4 μin) with proper finishing passes. The surface texture consists of overlapping craters that can be beneficial for some applications like mold surfaces.

5. Precision: Modern machines can hold tolerances within ±0.005 mm (±0.0002 in) or better, with positioning accuracy to 1 micron.

6. Repeatability: Once an electrode is made and program developed, identical cavities can be reproduced with high consistency.

7. Burr-free: Produces parts with minimal burrs compared to conventional machining, reducing secondary operations.

Limitations and Challenges

While sinker EDM is a powerful technology, it does have some limitations:

1. Material Conductivity Requirement: Only works on electrically conductive materials. Non-conductive ceramics, plastics, and composites cannot be machined by EDM.

2. Electrode Wear: The electrode erodes during the process, requiring compensation in the electrode design or multiple electrodes for high-precision work.

3. Slower than Conventional Machining: Material removal rates are generally lower than milling or turning, especially for large volumes of material.

4. Surface Layer Effects: The high temperatures create a recast layer (white layer) on the machined surface that may require post-processing for some applications.

5. Higher Energy Consumption: The process requires significant electrical power compared to conventional machining.

6. Dielectric Fluid Handling: The hydrocarbon oils used require proper handling, filtration, and disposal systems.

Despite these limitations, sinker EDM remains the best or only option for many challenging machining applications.

Industrial Applications

Sinker EDM finds applications across numerous industries where precision machining of hard materials or complex shapes is required:

1. Mold and Die Making: Perhaps the most common application, used to create injection molds, die casting dies, and stamping dies with complex cavities and fine details.

2. Aerospace: Machining turbine blades, engine components, and other high-temperature alloy parts that must maintain integrity in extreme conditions.

3. Medical Devices: Production of surgical instruments, implants, and other medical components requiring high precision and excellent surface finish.

4. Automotive: Manufacturing fuel injection components, transmission parts, and other precision automotive components.

5. Electronics: Creating micro-scale features for connectors and other electronic components.

6. Defense: Machining hardened components for firearms, guidance systems, and other military applications.

7. Prototyping: Rapid production of complex prototype parts without the need for special tooling.

The technology continues to find new applications as materials become more advanced and part geometries more complex.

Future Trends in Sinker EDM Technology

Sinker EDM technology continues to evolve with several exciting developments on the horizon:

1. Automation Integration: Increased integration with robotic loading/unloading systems and automated electrode changers to enable lights-out manufacturing.

2. Advanced Controls: Machine learning algorithms that can optimize parameters in real-time based on spark monitoring and historical data.

3. Hybrid Processes: Combining EDM with other technologies like laser machining or additive manufacturing for enhanced capabilities.

4. Micro-EDM: Pushing the boundaries of precision with capabilities to machine features smaller than 10 microns.

5. Green Technologies: Development of more environmentally friendly dielectric fluids and energy-efficient power supplies.

6. Additive Electrode Manufacturing: Using 3D printing to create complex electrode geometries that would be difficult or impossible to machine conventionally.

7. Digital Twin Technology: Virtual simulations of the EDM process to optimize parameters before physical machining begins.

As these technologies mature, sinker EDM will become even more precise, efficient, and accessible to manufacturers of all sizes.

Frequently Asked Questions

Q: What’s the difference between sinker EDM and wire EDM?

A: Sinker EDM uses a shaped electrode that sinks into the workpiece to create 3D cavities, while wire EDM uses a thin, continuously moving wire to cut 2D profiles. Sinker EDM is better for complex 3D shapes, while wire EDM excels at through-cutting precise contours.

Q: How small of features can sinker EDM machine?

A: With micro-EDM capabilities, features as small as 0.005 mm (5 microns) can be produced, though typical commercial applications work with features down to about 0.05 mm. The limit depends on electrode size, machine precision, and process control.

Q: Is sinker EDM expensive compared to conventional machining?

A: The initial setup (electrode fabrication) and slower material removal make EDM more costly for simple parts. However, for complex geometries in hard materials or when considering reduced secondary operations, EDM can be more cost-effective overall.

Q: How does electrode wear affect the machining process?

A: All electrodes experience some wear during EDM. This is compensated for by: 1) Oversizing the electrode to account for wear, 2) Using multiple electrodes (roughing and finishing), or 3) CNC path compensation that adjusts for progressive wear.

Q: Can sinker EDM be used for mass production?

A: While traditionally used for prototyping and tooling, modern automated sinker EDM systems with quick-change electrodes are increasingly used for production runs, especially for complex parts in hard materials where it may be the only viable method.

Conclusion

Sinker EDM represents a remarkable fusion of electrical engineering and precision manufacturing that has revolutionized our ability to machine complex shapes in ultra-hard materials. By harnessing controlled electrical sparks rather than mechanical force, this technology overcomes many limitations of conventional machining methods.

From its essential components to the sophisticated control of spark parameters, sinker EDM offers manufacturers unparalleled capabilities for producing molds, dies, and precision components across industries. While the process has some limitations in speed and material requirements, its advantages in precision, complexity, and ability to handle hardened materials make it indispensable in modern manufacturing.

As the technology continues to evolve with automation, advanced controls, and integration with other processes, sinker EDM will undoubtedly remain a cornerstone of precision manufacturing for years to come.

Recommended Reading: Learn more about advanced manufacturing technologies in our articles on Wire EDM and The Future of CNC Machining.

Need Precision CNC Machining for Your Mold Components?

We specialize in custom CNC machining of mold inserts, slide cores, ejector plates, mold bases, and lifters

all made to your exact drawings and specifications.

👉 Let’s Build Your Next Project Together!

Tell us your needs and upload your drawings — we’ll get back within 24 hours.

How Does Sinker EDM Work? The Complete Guide to Electrical Discharge Machining

In the world of precision manufacturing, sinker EDM (Electrical Discharge Machining) stands out as a revolutionary technology capable of creating complex shapes in extremely hard materials with micron-level accuracy. But how exactly does this fascinating process work? This comprehensive guide will explain the science behind sinker EDM, its key components, working principles, and why it’s become indispensable in industries ranging from aerospace to medical device manufacturing.

Unlike conventional machining methods that rely on physical cutting tools, sinker EDM uses controlled electrical sparks to erode material, allowing it to machine materials that would be impossible to cut with traditional methods. Whether you’re a manufacturing professional looking to deepen your understanding or simply curious about advanced machining technologies, this article will illuminate the inner workings of sinker EDM.

Table of Contents

- What is Sinker EDM?

- Key Components of a Sinker EDM Machine

- The Working Principle of Sinker EDM

- Electrode Materials and Design

- The Role of Dielectric Fluid

- Process Control and Parameters

- Advantages of Sinker EDM

- Limitations and Challenges

- Industrial Applications

- Future Trends in Sinker EDM Technology

What is Sinker EDM?

Sinker EDM, also known as ram EDM, die-sinking EDM, or conventional EDM, is a non-traditional machining process that uses electrical discharges (sparks) to remove material from a workpiece. The name “sinker” comes from the process where an electrode “sinks” into the workpiece, creating a negative impression of its shape.

This process was first observed in the 1770s but wasn’t developed into a practical manufacturing technique until the 1940s. Today, modern CNC-controlled sinker EDM machines can achieve tolerances as tight as ±0.005 mm (±0.0002 inches), making them invaluable for precision applications.

Unlike wire EDM which uses a thin wire as an electrode, sinker EDM uses custom-shaped electrodes (typically made of graphite or copper) that are precisely machined to match the desired cavity shape. This makes it particularly useful for creating complex 3D geometries, molds, and dies that would be difficult or impossible to produce with conventional machining.

The process is especially valuable for machining hardened steels, titanium, carbides, and other materials that are challenging to cut with traditional methods. Because there’s no physical contact between tool and workpiece, sinker EDM can machine delicate features without introducing mechanical stresses.

Key Components of a Sinker EDM Machine

A typical sinker EDM system consists of several critical components that work together to create precise electrical discharges and control the machining process:

1. Power Supply: Generates pulsed DC current that creates the sparks between electrode and workpiece. Modern machines use adaptive power supplies that can adjust parameters in real-time for optimal machining.

2. Electrode: The tool (usually graphite or copper) that is shaped to form the desired cavity. The electrode wears during the process and may need to be replaced or re-machined for high-precision work.

3. Workpiece: The material being machined, which must be electrically conductive. Common materials include steel, titanium, tungsten carbide, and conductive ceramics.

4. Dielectric System: Includes a reservoir, pump, filtration system, and nozzles to deliver dielectric fluid (typically hydrocarbon oil) to the machining area. This fluid serves multiple critical functions we’ll explore later.

5. Servo Control System: Maintains the precise gap (typically 0.01-0.05 mm) between electrode and workpiece by constantly adjusting the position based on spark conditions.

6. CNC Control: Modern machines use computer numerical control to manage electrode movement, machining parameters, and often include advanced features like adaptive control and process monitoring.

The Working Principle of Sinker EDM

The fundamental principle behind sinker EDM is surprisingly simple: controlled electrical sparks erode material from both the electrode and workpiece. Here’s a step-by-step breakdown of how the process works:

Step 1: The electrode (shaped to the desired cavity form) is positioned close to the workpiece with a small gap (0.01-0.05 mm) filled with dielectric fluid.

Step 2: The power supply generates a high-frequency pulsed DC voltage (typically 50-300V) between the electrode and workpiece. When the voltage reaches the breakdown point of the dielectric fluid (about 15,000-30,000 V/mm), it ionizes the fluid, creating a conductive plasma channel.

Step 3: A spark jumps across this ionized channel, reaching temperatures of 8,000-12,000°C (14,432-21,632°F) at the point of impact. This intense heat melts and vaporizes microscopic amounts of material from both surfaces.

Step 4: The dielectric fluid then flushes away the eroded particles and cools the area, while also deionizing the gap to prevent continuous arcing.

Step 5: The servo system advances the electrode to maintain the optimal gap distance as material is removed. This cycle repeats thousands to millions of times per second, gradually sinking the electrode shape into the workpiece.

The entire process occurs in a dielectric fluid bath which serves multiple purposes: it acts as an insulator until the breakdown voltage is reached, cools the workpiece, flushes away debris, and helps prevent excessive electrode wear.

Electrode Materials and Design

The choice of electrode material significantly impacts the sinker EDM process’s efficiency, accuracy, and cost. The most common materials are:

Graphite: The most popular choice for most applications due to its excellent machinability, good wear resistance, and high melting point (3,600°C). Graphite electrodes can be easily machined to complex shapes and are relatively inexpensive.

Copper: Offers better surface finish than graphite but wears faster. Often used for fine-detail work or when excellent surface finish is required. Copper tungsten alloys are used for tungsten carbide machining.

Brass: Primarily used for specialized applications like small-hole drilling EDM. It provides stable sparking but has higher wear rates.

Electrode design is a critical factor in sinker EDM. The electrode must account for:

- Overburn (the gap between electrode and final cavity size)

- Expected wear rates during machining

- Multiple electrodes may be needed for roughing and finishing passes

- Venting channels may be required for deep cavities to allow dielectric flow

Modern CAD/CAM systems can automatically generate electrode designs that account for these factors, significantly reducing setup time and improving accuracy.

The Role of Dielectric Fluid

The dielectric fluid in sinker EDM serves four critical functions:

1. Insulation: Acts as an insulator between electrode and workpiece until the breakdown voltage is reached, allowing controlled sparking rather than continuous arcing.

2. Cooling: Rapidly cools the extremely hot spark zone to prevent thermal damage to both workpiece and electrode.

3. Flushing: Carries away eroded particles (called “swarf”) from the machining gap. Proper flushing is essential to prevent arcing on accumulated debris.

4. Deionization: After each spark, the fluid must quickly deionize to restore its insulating properties for the next pulse.

The most common dielectric fluids are hydrocarbon oils, which offer good insulating properties and high flash points. For some applications, deionized water or special synthetic fluids may be used. The fluid is continuously filtered to remove particles and maintain consistent machining performance.

Advanced machines often have multiple flushing options:

- Pressure flushing through the electrode

- Suction flushing

- Jet flushing

- Orbital flushing for complex cavities

Process Control and Parameters

Modern sinker EDM machines offer extensive control over numerous parameters that affect machining speed, surface finish, electrode wear, and accuracy:

Current (Amperage): Higher currents remove material faster but create larger craters and rougher surfaces. Roughing operations typically use 20-50A, while finishing might use 1-5A.

Pulse Duration (On-time): Longer pulses allow more energy to be delivered per spark, increasing removal rate but also increasing crater size. Typical range is 1-2000 microseconds.

Pulse Interval (Off-time): The time between sparks allows dielectric fluid to deionize and flush debris. Insufficient off-time can lead to arcing.

Polarity: Most sinker EDM uses positive polarity (electrode positive, workpiece negative) which generally results in better electrode wear characteristics.

Servo Control: The system constantly monitors spark conditions and adjusts the gap to maintain optimal machining. Advanced systems can detect different machining conditions and automatically adjust parameters.

Modern CNC sinker EDMs often feature:

- Adaptive control systems that optimize parameters in real-time

- Multiple machining passes with different parameters for roughing and finishing

- Orbital machining strategies that move the electrode in controlled patterns to improve flushing and accuracy

- Automated electrode changers for complex jobs requiring multiple electrodes

Advantages of Sinker EDM

Sinker EDM offers numerous advantages that make it indispensable for many manufacturing applications:

1. Machining Hard Materials: Can machine hardened steels, carbides, and exotic alloys that would be difficult or impossible to cut with conventional methods. The workpiece hardness doesn’t affect the EDM process.

2. Complex Geometries: Capable of producing intricate cavities, sharp internal corners, and complex 3D shapes that would be challenging with milling or grinding.

3. No Mechanical Forces: Since there’s no physical contact between tool and workpiece, there’s no risk of distorting delicate parts or tools breaking during machining.

4. Excellent Surface Finish: Can achieve surface finishes down to Ra 0.1 μm (4 μin) with proper finishing passes. The surface texture consists of overlapping craters that can be beneficial for some applications like mold surfaces.

5. Precision: Modern machines can hold tolerances within ±0.005 mm (±0.0002 in) or better, with positioning accuracy to 1 micron.

6. Repeatability: Once an electrode is made and program developed, identical cavities can be reproduced with high consistency.

7. Burr-free: Produces parts with minimal burrs compared to conventional machining, reducing secondary operations.

Limitations and Challenges

While sinker EDM is a powerful technology, it does have some limitations:

1. Material Conductivity Requirement: Only works on electrically conductive materials. Non-conductive ceramics, plastics, and composites cannot be machined by EDM.

2. Electrode Wear: The electrode erodes during the process, requiring compensation in the electrode design or multiple electrodes for high-precision work.

3. Slower than Conventional Machining: Material removal rates are generally lower than milling or turning, especially for large volumes of material.

4. Surface Layer Effects: The high temperatures create a recast layer (white layer) on the machined surface that may require post-processing for some applications.

5. Higher Energy Consumption: The process requires significant electrical power compared to conventional machining.

6. Dielectric Fluid Handling: The hydrocarbon oils used require proper handling, filtration, and disposal systems.

Despite these limitations, sinker EDM remains the best or only option for many challenging machining applications.

Industrial Applications

Sinker EDM finds applications across numerous industries where precision machining of hard materials or complex shapes is required:

1. Mold and Die Making: Perhaps the most common application, used to create injection molds, die casting dies, and stamping dies with complex cavities and fine details.

2. Aerospace: Machining turbine blades, engine components, and other high-temperature alloy parts that must maintain integrity in extreme conditions.

3. Medical Devices: Production of surgical instruments, implants, and other medical components requiring high precision and excellent surface finish.

4. Automotive: Manufacturing fuel injection components, transmission parts, and other precision automotive components.

5. Electronics: Creating micro-scale features for connectors and other electronic components.

6. Defense: Machining hardened components for firearms, guidance systems, and other military applications.

7. Prototyping: Rapid production of complex prototype parts without the need for special tooling.

The technology continues to find new applications as materials become more advanced and part geometries more complex.

Future Trends in Sinker EDM Technology

Sinker EDM technology continues to evolve with several exciting developments on the horizon:

1. Automation Integration: Increased integration with robotic loading/unloading systems and automated electrode changers to enable lights-out manufacturing.

2. Advanced Controls: Machine learning algorithms that can optimize parameters in real-time based on spark monitoring and historical data.

3. Hybrid Processes: Combining EDM with other technologies like laser machining or additive manufacturing for enhanced capabilities.

4. Micro-EDM: Pushing the boundaries of precision with capabilities to machine features smaller than 10 microns.

5. Green Technologies: Development of more environmentally friendly dielectric fluids and energy-efficient power supplies.

6. Additive Electrode Manufacturing: Using 3D printing to create complex electrode geometries that would be difficult or impossible to machine conventionally.

7. Digital Twin Technology: Virtual simulations of the EDM process to optimize parameters before physical machining begins.

As these technologies mature, sinker EDM will become even more precise, efficient, and accessible to manufacturers of all sizes.

Frequently Asked Questions

Q: What’s the difference between sinker EDM and wire EDM?

A: Sinker EDM uses a shaped electrode that sinks into the workpiece to create 3D cavities, while wire EDM uses a thin, continuously moving wire to cut 2D profiles. Sinker EDM is better for complex 3D shapes, while wire EDM excels at through-cutting precise contours.

Q: How small of features can sinker EDM machine?

A: With micro-EDM capabilities, features as small as 0.005 mm (5 microns) can be produced, though typical commercial applications work with features down to about 0.05 mm. The limit depends on electrode size, machine precision, and process control.

Q: Is sinker EDM expensive compared to conventional machining?

A: The initial setup (electrode fabrication) and slower material removal make EDM more costly for simple parts. However, for complex geometries in hard materials or when considering reduced secondary operations, EDM can be more cost-effective overall.

Q: How does electrode wear affect the machining process?

A: All electrodes experience some wear during EDM. This is compensated for by: 1) Oversizing the electrode to account for wear, 2) Using multiple electrodes (roughing and finishing), or 3) CNC path compensation that adjusts for progressive wear.

Q: Can sinker EDM be used for mass production?

A: While traditionally used for prototyping and tooling, modern automated sinker EDM systems with quick-change electrodes are increasingly used for production runs, especially for complex parts in hard materials where it may be the only viable method.

Conclusion

Sinker EDM represents a remarkable fusion of electrical engineering and precision manufacturing that has revolutionized our ability to machine complex shapes in ultra-hard materials. By harnessing controlled electrical sparks rather than mechanical force, this technology overcomes many limitations of conventional machining methods.

From its essential components to the sophisticated control of spark parameters, sinker EDM offers manufacturers unparalleled capabilities for producing molds, dies, and precision components across industries. While the process has some limitations in speed and material requirements, its advantages in precision, complexity, and ability to handle hardened materials make it indispensable in modern manufacturing.

As the technology continues to evolve with automation, advanced controls, and integration with other processes, sinker EDM will undoubtedly remain a cornerstone of precision manufacturing for years to come.

Recommended Reading: Learn more about advanced manufacturing technologies in our articles on Wire EDM and The Future of CNC Machining.

Example HTML for Embedding an EDM Video

Here’s how you might embed an EDM process video in your WordPress post:

<div class="video-container">

<iframe width="560" height="315"

src="https://www.youtube.com/embed/EDM_PROCESS_VIDEO_ID"

frameborder="0"

allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture"

allowfullscreen>

</iframe>

</div>